Extrusion...

Extrusion...

Silicone product...

Silicone product...

Extrusion...

Extrusion...

Silicone product...

Silicone product...

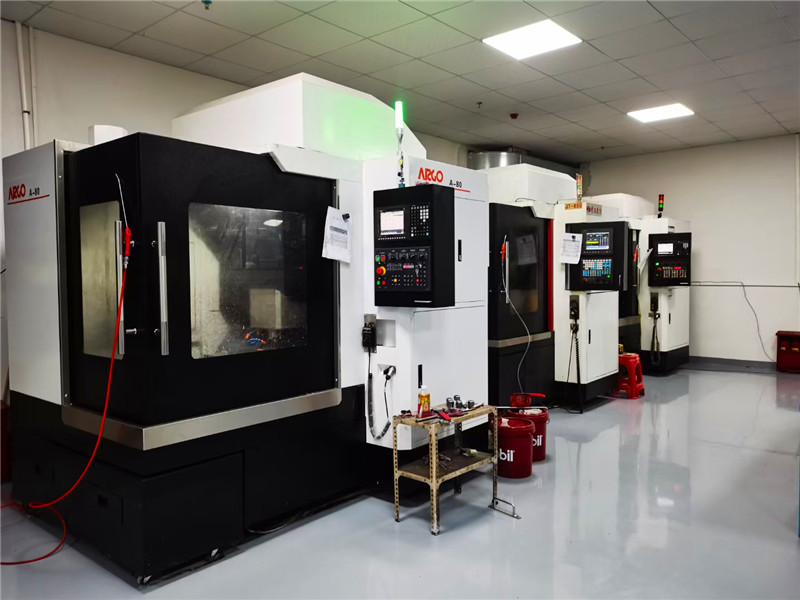

Mold workshop

Mold workshop

Video of silica ...

Video of silica ...

Silicone product...

Silicone product...

Mold workshop

Mold workshop

Extrusion...

Extrusion...

Silicone product...

Silicone product...

Mold workshop

Mold workshop

Extrusion...

Extrusion...

Plastic workshop

Plastic workshop

Pressroom

Pressroom

Sample room

Sample room

Workshop

Workshop

Mold workshop

Mold workshop

Extrusion...

Extrusion...

Secondary...

Secondary...

Plastic workshop

Plastic workshop

Pressroom

Pressroom

Sample room

Sample room

Products...

Products...

Liquid silicone ...

Liquid silicone ...

Mold workshop

Mold workshop

Extrusion...

Extrusion...

Plastic workshop

Plastic workshop

Secondary...

Secondary...

Pressroom

Pressroom

Sample room

Sample room

Products...

Products...

Solid silicone...

Solid silicone...

Mold workshop

Mold workshop

Extrusion...

Extrusion...

Plastic workshop

Plastic workshop

Secondary...

Secondary...

Pressroom

Pressroom

Sample room

Sample room

Mold Laboratory

Mold Laboratory

Workshop

Workshop

Mold workshop

Mold workshop

The Typical Structure of Precision Plastic MoldThe typical structure of precision plastic injection mold1. Injection partsThe cavity is injection directly, the parts of plastic injection is composed of male die and female die.2.Gating SystemGating system:the jet nozzle will lead the plastic to the runner of impression which is composed by main runner,partial runner,sprue gate and quench well.3.Guide PartThe guide part is used to make sure the moving die and fixed mold can be aimed which is composed by GP,positioning block,EGP and so on.4. The structure of Parting Shaft CoreBefore the outer part or plastic of side hole be pushed out, it should be done side parting then can smooth demolding. Common structure including slider,angle pin and so on.5. Ejection DeviceThe device is used to push out the plastic from mold, common structure including pipe-jacking,ejection part and angle pin and so on.6.Cooling and Heating SystemsIn order to satisfy the mold tempreture requirement of injection, the mold have cooling and heating system which will have cooling water channel,heating or oil matter in the mold.

1st,Plastic Mold--5 steps of produce processWith the change in people's aesthetic standards,Multi-color plastic mold is very popular plastic products, below are the produce steps of dual-color plastic injection.First step: Technology analysis of plastic productsThe designer should analysis whether the design of plastic product meet plastic injection machining principle,and discuss with the producer to reach consensus.They need to discuss the product'sgeometrical shapes,size and appearance to aviod the non-neccessory complex part.2nd, Mold structure designThe quality mold not only need premuim produce machine and better skilled dualcolor injection worker but also required good mold design which is a very important fact. Especially regarding to the comple mold, the mold design will have above 80% effect.A good mold design should meet the customer's requirement to reach lower cost,easy of manufacture and shorter produce time.To reach this gold not only need to understand customer's requirement but also know the injection machine,manufacture technology,mold structure and the process capability of mold factory. Above all, to improve mold design level, must do the following:1. Understand each details of the each mold design and the purpose of each parts;2. Refer back similar design when designing noew mold and learn the mold manufacture and product produce situation, to absorb the experience;3. To understand better the relationship of mold and injection machine, need to learn more knowledge of injection machine produce process;4. Need to learn more product produce process to know the feature and limitation of each production;5. To absorb the experience through the tryout result and modify situation;6. Its better trying to use the previous good mold structure when designing;7. Need to learn more knowledge of the affect to the product of mold in water;8. Research the special mold structure and learn the latest mold technology.3rd,Identify the materials and choose the standardsWhen choosing the mold material, not only need to consider the precision and quality of product but also need to consider the produce and heat treatment capability of the mold factory.Besides, to shorter the lead times, need to use the standards parts as most as possible. 4th,Parts Processing and mold assembleBesides the coodinate of best structure and rational tolerance,the parts process and mold assemble is also very important for the precision of injection mold. So, process precision and technology have absolute predominance when choose dual-color injection. The product tolerance including below parts:1. The tolerance of mold manufacture is about one-third;2. The tolerance of mold wear is about one-sixth;3. The tolerance of product produce uneven contraction is about one-third;4. The tolerance of the difference between precontracts and actual contracts is about one-sixth.5th,Try OutIt's only finish about 70%-80% after the mold design and assemble for the whole manufacture process. For the tolerance of the difference between pre-contracts and actual contracts, demould successful or not, The affect of gate size,position,shapr to the product's precision and appearence, all of these need to check by try out. So,try out is a required step to check the mold acceptable or not and choose thebest molding technology.

The maintenance of plastic productThe maintenance of plastic product is more important than repair product, The more repair times the shorter of product's useful life;The better of maintencance the longer of product's useful life. There are 3 main points of maintenance of plastic product:1. Daily maintenance: all the move parts such as thimle,slide,column,guide sleeve fuel and mold clean, these are all need to do daily maintenance; 2. Regularly maintenance: including clean exhausting-slot,air exhaust slots,modify the wear and tear parts;3. Appearance maintenance:painting on the outside of mould to avoid rusting, the movable and fixed mould shoul be painting when use the mold. To aovid dust get in the cavity, the plastic product should be sealed when save the plastic product.

Chinese name: 班国伟

English name: Tom Ban

Mobile: +86-13570810641

E-Mail:tomban@minghuigp.com

Chinese Name: 阮氏秋芳

English name:Phuong Nguyen

Mobile: +86-0928.96.6886

E-Mail:phuongnguyen@tripleleaves-vn.com

Chinese name: 阮氏玉英

English name:Annie

Mobile:+86-0976340901

E-Mail:purchasing01@tripleleaves-vn.com

Minghui Group was founded in 2009 and is a comprehensive enterprise that integrates development, design, production, and trade.We specialize in the production design and mold manufacturing of various silicone rubber and plastic products. We have offices and manufacturing factories located in Hong Kong, Shanghai, Shenzhen, Dongguan, and Vietnam.For many years, the company has adhered to the principle of 'people-oriented, quality first, professional focus, and innovative development', continuously committed to technological...

86-13570810641